Love Longyuan-the 15th batch of achievements of Doctor Service Group on probation: 221–223 Wang KK (2015) The current situation and thinking of material processing industry in Gansu Province. Kudrya A, Sokolovskaya E, Ngo K, Kaikibaeva A (2018) Relation between the nonuniformity of the properties and the structure of large forgings. Zhang FL, Yuan ZH, Dong S, Kang J (2018) The study of the cavity inside heavy forgings based on the temperature field detection model. Tanaka Y, Sato I (2011) Development of high purity large forgings for nuclear power plants.

The equation provided a theoretical basis for selecting the press tonnage during the forging process with liquid core. We constructed the relationship equation between the forming pressure and the other three factors in Origin. Fifty-three sets of forging parameters data were recorded including the solid-phase thickness, the reduction amount, the pressing speed and the forming pressure in each group. Four groups of the physical models of the multilayer gradient were also established under laboratory conditions. We mastered the deformation law during the forging process with liquid core. The significant factors were acquired by the range analysis which affected the values of the equivalent strain and the equivalent stress in the solid-phase region, the solid–liquid two-phase region and the liquid-phase region. Three orthogonal tests were designed to obtain the results with solid-phase thickness, reduction amount and pressing speed as three factors.

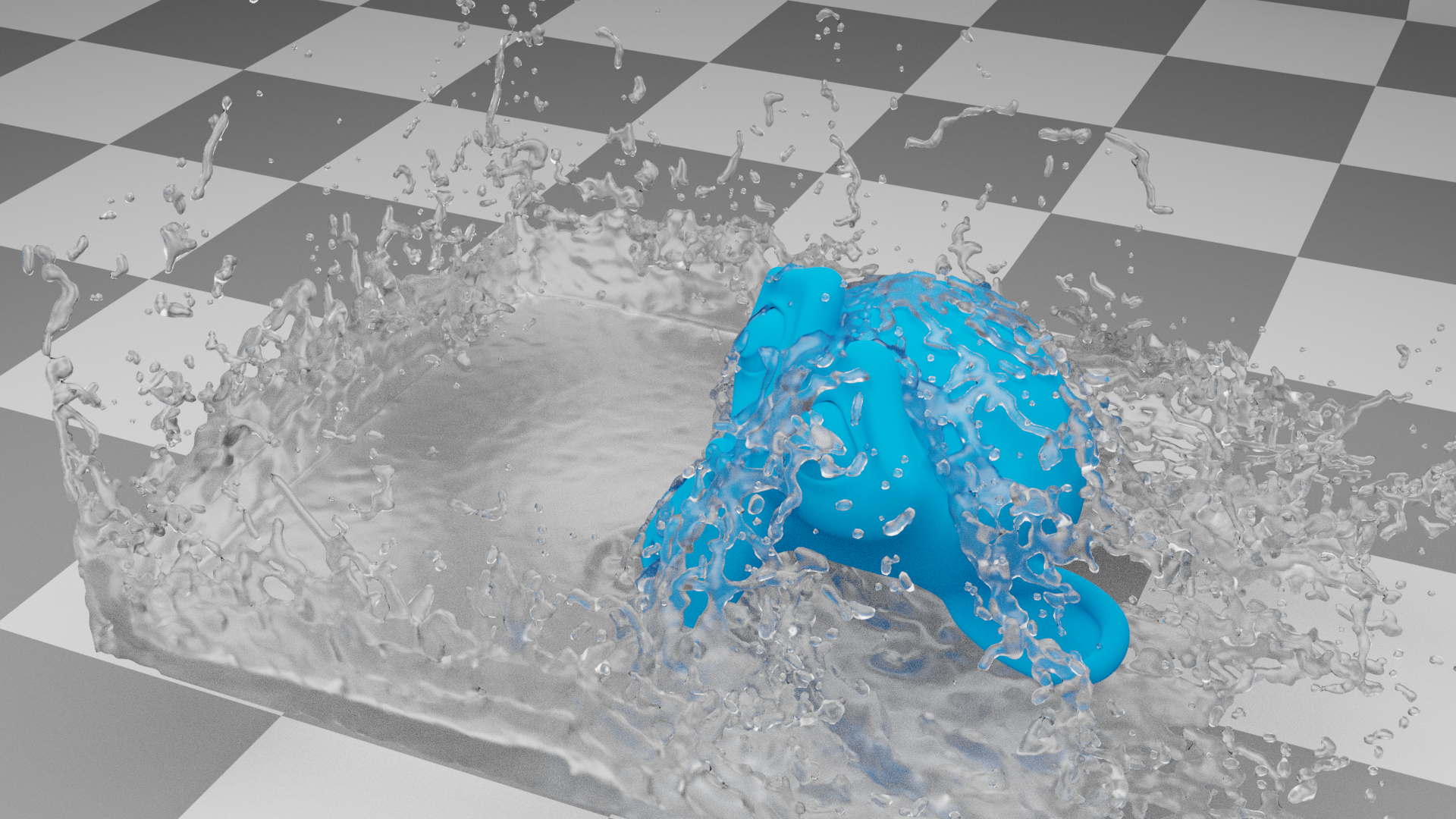

LIQUID SIMULATION SOFTWARE

DEFORM-3D software was used to simulate the forging process with liquid core.

0 kommentar(er)

0 kommentar(er)